Did you know you can Change Feeds and Speeds with the pendant while your machine is running? This allows you to tweak and fine-tune your job on the fly.

Vision’s 16 series engraving machines and larger CNC routers and engravers come with advanced V-Touch Technology, which features a multi-functional touchscreen pendant. Vision’s V-touch pendant provides many benefits, making the operators’ job much easier. You can start and stop, set zero, set feed rate, jog your machine, and much more all on the pendant. Not having to be near the controller will provide the machine operator with high mobility and the freedom to work more efficiently, creating a highly productive machine shop.

For this Engraving and CNC Routing Quick tip, we are going to change feeds and speeds from the Pendent.

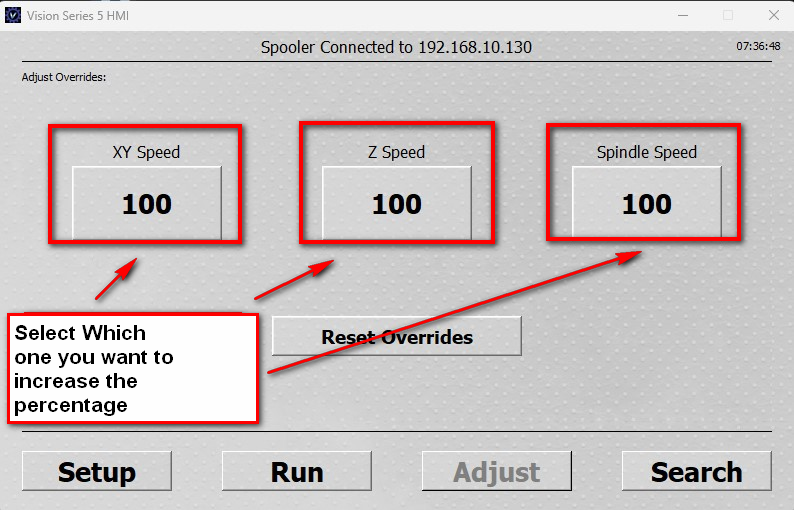

The ability to speed up or slow down the speed of the XY, and Z axis, and spindle speed is based on a percentage.

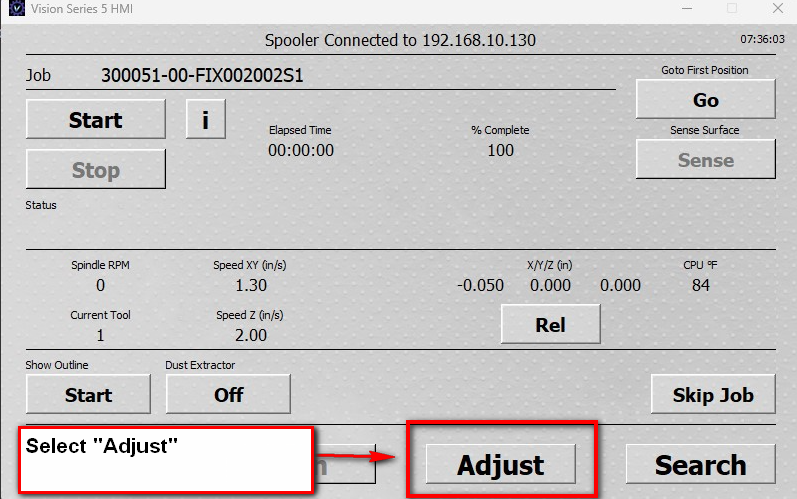

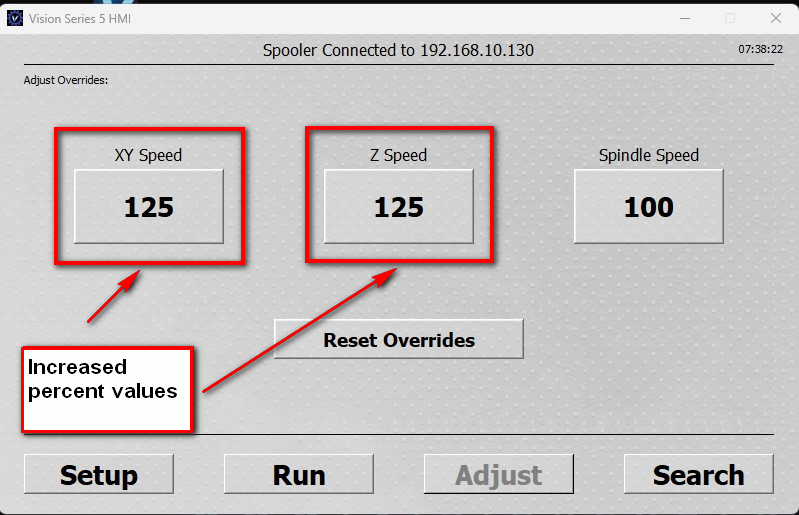

- First, select the Adjust button on the pendant. Percentage adjustment can be decreased or increased at any time while running the engraving or routing job, as long as you have the job loaded.

2. Select which setting you want to speed up by percentage, the XY Speed, Z Speed, or Spindle Speed.

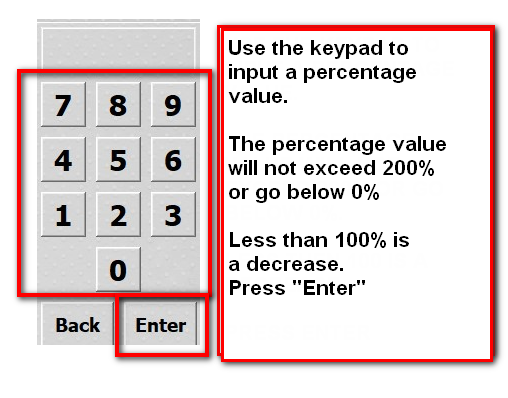

3. Use the keypad to adjust the speed by percentage. You cannot increase past 200% or go lower than 0% on any of the values. When you are done inputting your percentage increase, press ENTER key.

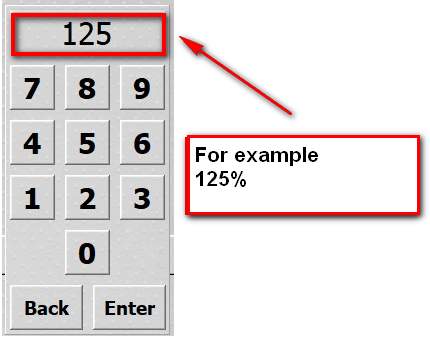

4. As an example if you enter 125%, you will increase the speed by 25%

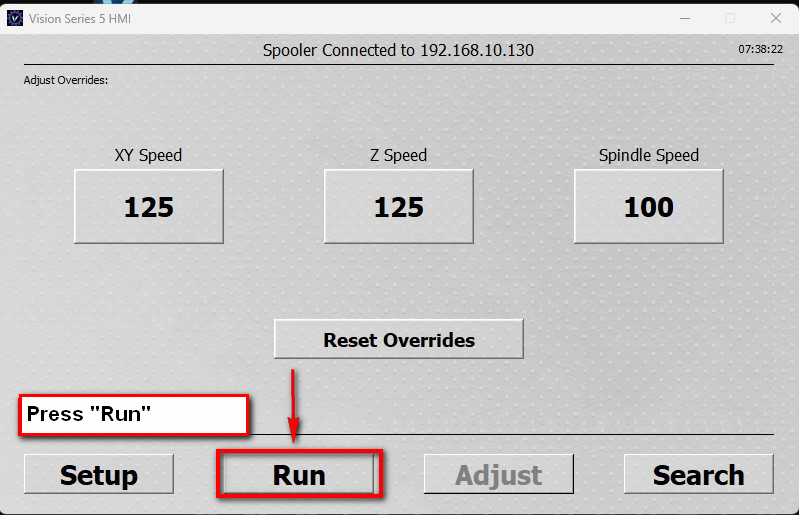

5. After you have increased the percentage, press the “RUN.”

6. Your engraving or routing job will now run at the newly set percentage value when it reaches the next point or segment of the job.

7. While adjusting speeds, make sure not to exceed any safety limits or operational constraints to prevent damage to your engraving machine or CNC router or workpieces.

8. At the end of the job the percentage increases default back to 100%.

These controls provide operators with the flexibility to fine-tune the speeds of various components during machining or other operations for optimal performance and precision.

Check back next month for more Engraving or CNC Routing Quick Tips. Contact Vision Engraving & Routing Systems to learn more about Changing Feeds and Speeds from the Pendent or to request a free online engraving demo. Visit us online today at www.visionengravers.com or call 1-888-637-1737. Be sure to check out our All Post List, lots of helpful Engraving Machines and CNC Routing info there.