If you have purchased a 3HP high speed routing spindle from Vision you would have received a general purpose hard plastic routing bit. This is a single fluted end mill from the company Onsrud and it is labeled 63-712. This quick tip will show you how to calculate the cutting rate based on the manufacturer’s formula.

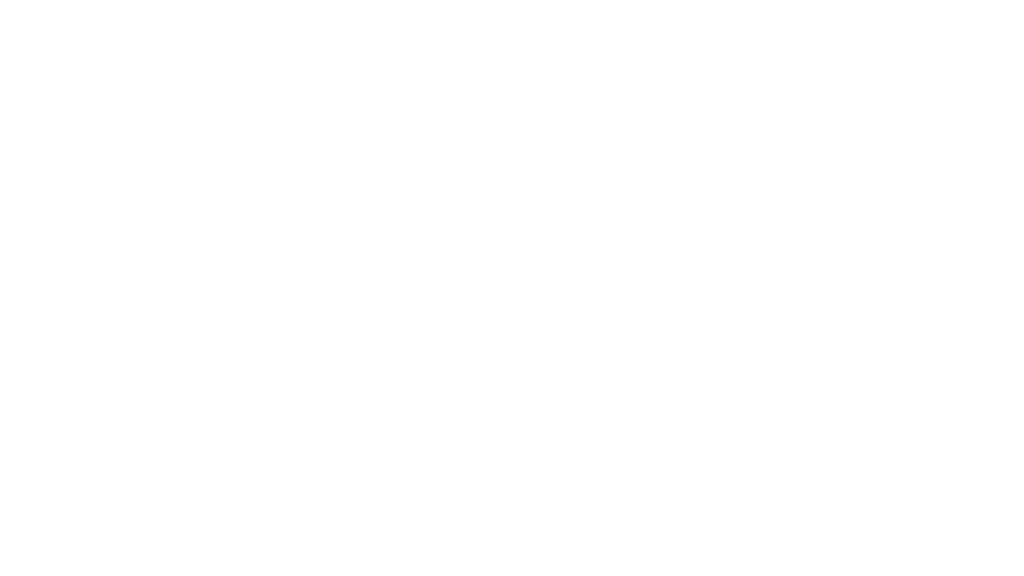

The chip load chart and formula can be found here:

https://www.onsrud.com/xdoc/FeedSpeeds

Click on “Hard Plastic Cutting Data”.

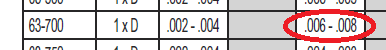

The left side of the chart refers to the tool series. In this case, 63-712 is part of the 63-700 series. The top of the chart refers to the tool cutting edge diameter. This refers the fifth column from the left which is 1/8” for the 63-712 tool.

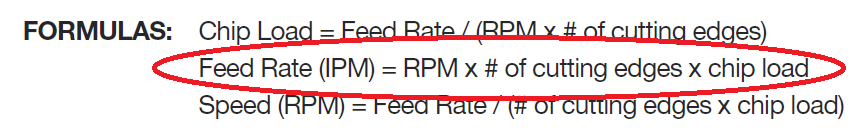

The formula we are interested in is Feed Rate (IPM) = RPM x # of cutting edges x chip load. This will give us a feed rate in inches per minute. RPM means Revolutions Per Minute and is a measure of how fast the spindle is rotating. The max RPM for the 3hp router on your Vision machine is 18,000.

Let’s arbitrarily choose an RPM of 14,000. We have only 1 cutting edge and a chip load range of .006-.008 (from the chart).

We can do two calculations using both the low and high ends of the chip load range. The calculations look like this:

14,000 x 1 x .006 = 84

14,000 x 1 x .008 = 112

So at 14,000 RPM the manufacturer recommends running the tool at 84-112 inches per minute. Vision software settings, however, are in inches per second (IPS). You will have to divide the calculated feed rate here by 60 to convert IPM to IPS for the Vision Software. This looks like the following:

84 (IPM) / 60 = 1.4 IPS

112 (IPM) /60 = 1.87 IPS

Keep in mind that these are very general calculations for a broad range of hard plastics. Nylon will cut differently than acrylic and different still from PVC. The best use of this method is to calculate a starting point with feed rates and RPM. Use this information to experiment and run test cuts. From there you can make changes and “dial-in” your RPM and feed rate to get a cut that is the best combination of quality and speed.