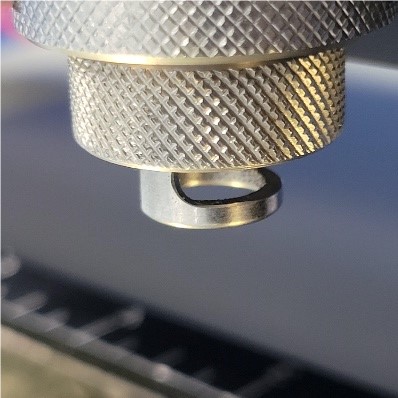

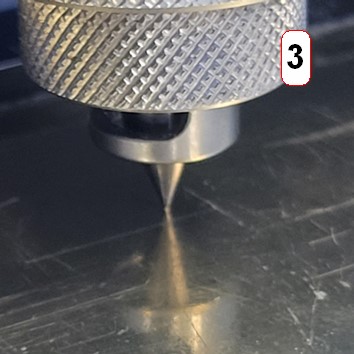

1) Install the metal nose cone.

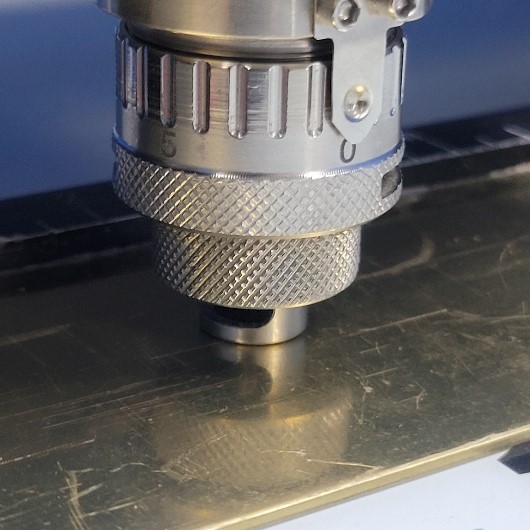

2) Rotate the micrometer all the way to the top when you can no longer turn it stop. Come down 3 complete turns/revolutions, passing 0 twice and stopping on 0.

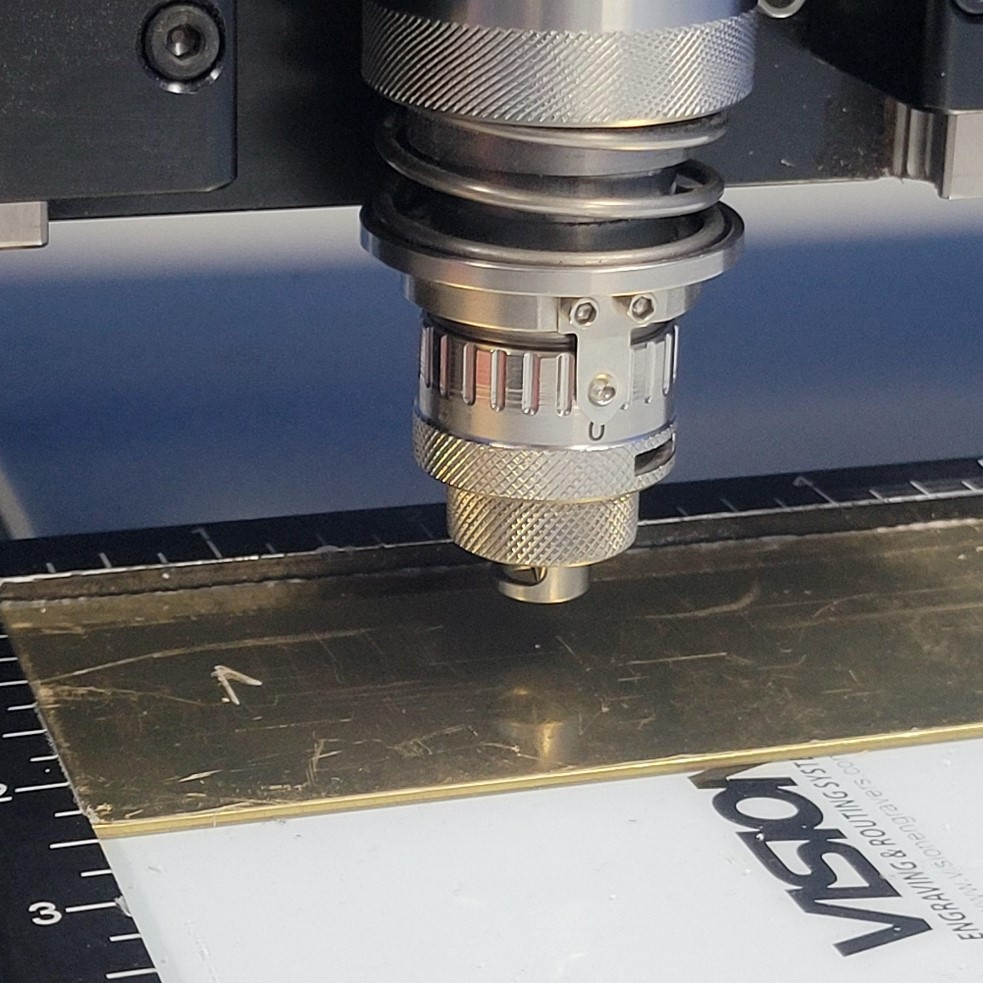

3) Bring the spindle out over a flat spot on the table and place a piece of material on the table flat. Insert the tool you want to use into the spindle and make sure the tool is snug in the spindle.

4) Lower the spindle until it is about 1/4” away from the flat piece of material on the table.

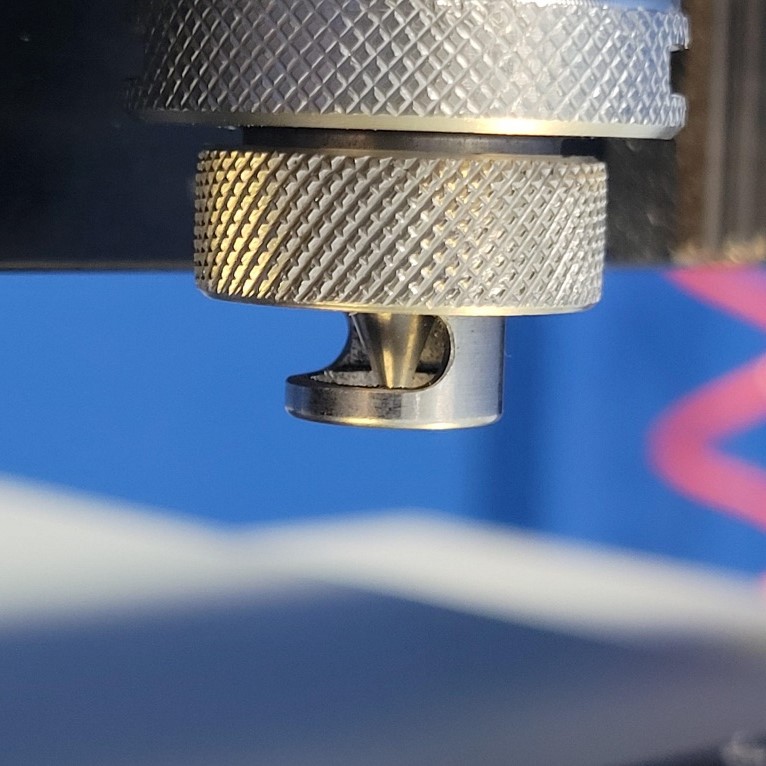

a) Holding the cutting tool’s shaft with one hand.

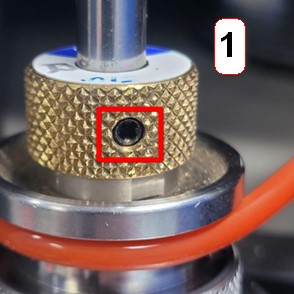

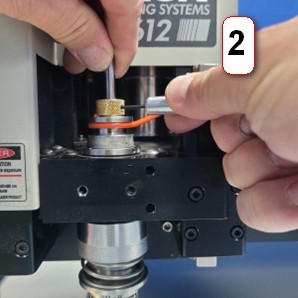

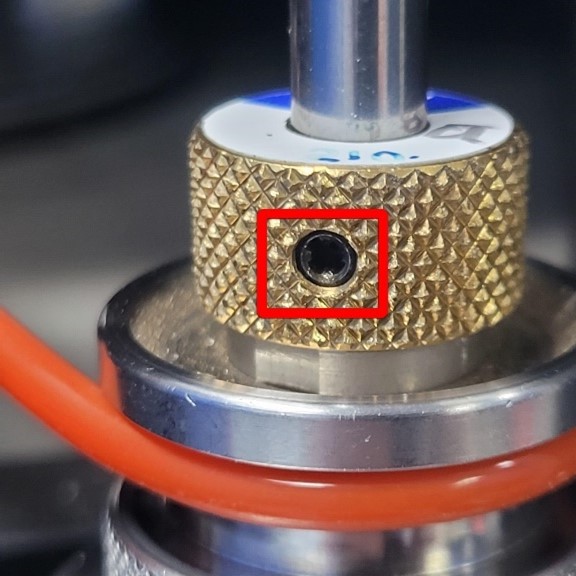

b) Loosen the set screw on the brass knob using the cutter wrench with the other hand.

c) Slowly lower the cutter, until the tip of the tool touches the material.

5) DO NOT tighten the set screw in the brass knob, this needs to remain free floating.

6) Go back to pendent and lower the spindle all the way down until the metal nose cone touches the material, along with the tip of the free-floating tool. This will push the tool up, making it even with the metal nose cone.

7) Once the nose cone is touching the material, double check the micrometer on the spindle and make sure it’s still on 0.

8) Leave the nose cone and tool on the surface of the material and tighten up the set screw in the brass knob on the tool.

9) Your tool has now been zeroed.

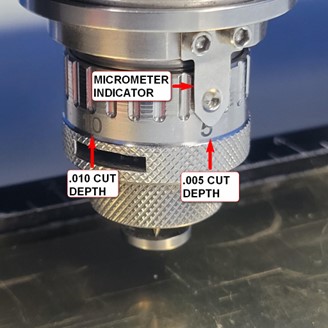

10) To make cutter depth changes, you dial the micrometer to the desired depth. For example, if you want a .005 depth, just dial to 5, or 10 for .010.

11) Remember to set proximity to enabled in the cut toolbox, before sending the job over.

12) Depending on the material, its recommended to use more passes and not be aggressive on removing too much material.

13) The nose cone will leave shadowing marks on the material that may require some additional buffing after engraving.

Check back next month for more Engraving Quick Tips. Contact Vision Engraving & Routing Systems to learn more about deep metal engraving, or to request a free online engraving demo. Visit us online today at www.visionengravers.com or call 1-888-637-1737.