Burnishing

Application

Burnishing is the process of removing the surface coating on metal, while polishing the exposed material, and is another method of engraving on brass and aluminum. The significant differences between burnishing and diamond drag engraving are the type of tool used and the use of the spindle motor. Keep in mind that a burnishing tool does not really “cut” the metal, but is more of a marking technique. Burnishing can also be used to engrave on glass.

The main advantage to burnishing on metals is that the tool produces a wider stroke width than drag engraving without the need for deeper cuts. The process removes only the top coating from the metal. The application is generally used on coated metals such as lacquered brass, where burnishing will only remove the top coating, exposing the bright brass underneath. To the engraver operator, this means that the size of the engraved character can be significantly larger than with diamond drag. On large plaques this is the preferred method.

Diamond-Drag Engraving

Application

The easiest and most common type of engraving is “diamond-drag”, also known as “scratch” engraving, for use on metals such as brass, aluminum, pewter, silver and gold. It gives equally effective results when done with either a manual or a computerized engraver and when done properly, it can pass for hand engraving.

Diamond-drag engraving is usually used to remove the top colored coating to expose the bare metal underneath (gold if brass or silver if aluminum). If the material has a clear coating instead of colored, the engraved area can be oxidized to blacken it and provide a contrast to the background.

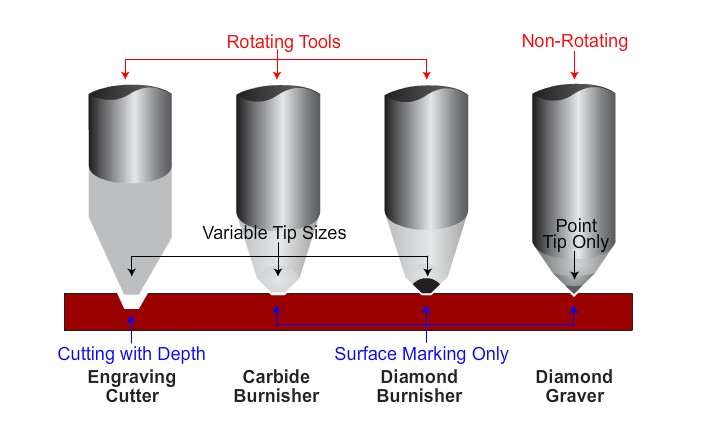

The below picture shows the basic differences between engraving cutters, burnishers and diamond drag tip designs. Note that for rotating cutters, the tip is not a sharp point, but a flat cutting edge. The width of this cutting edge determines the stroke width of the graphics when engraved. The diamond drag tip is a sharp point. In order to produce a wider stoke, the operator can vary the pressure applied to the cutting tool, or the number of passes made. Higher engraving pressure and/or more passes will create a wider stroke as well as more depth.