Diamond drag (also known as scratch engraving) is a permanent mark in metal that is not very deep. This is done for things like trophy plaques, anodized metal tags, etc. It is a quiet, quick, and clean process compared to deep engraving metal. You can get pretty detailed with this type of engraving because it only goes .001-.003 into the metal (depth depends on the hardness of the metal).

When doing diamond drag, consider using a multiple line font which will give it a bold look vs. a single line font which will be very thin. An example is Helv3 which is good for industrial use-nice clean and easy to read or even an outline font.

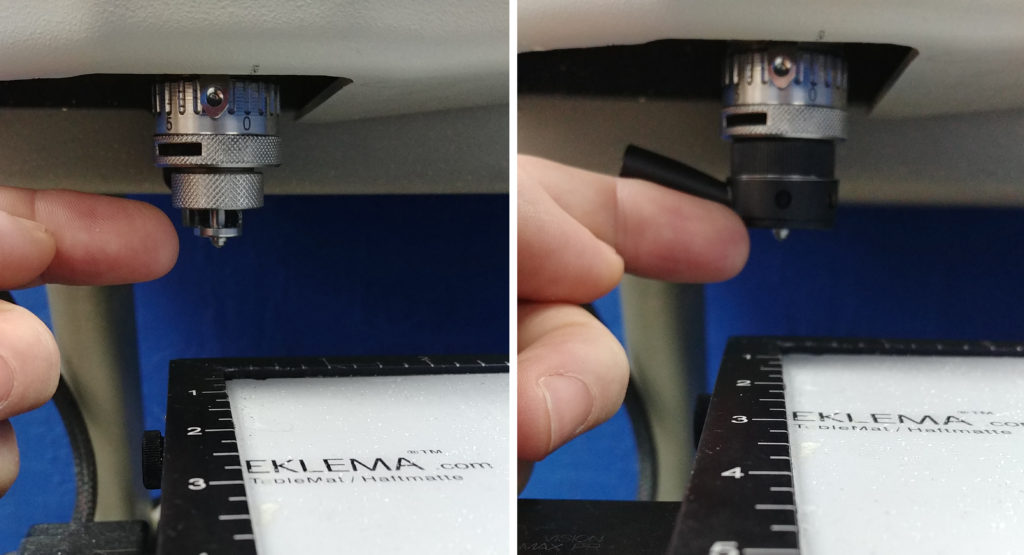

When setting the Diamond Drag tool (marked as NRD on the top of the brass collar), make sure the tip of the tool is at least 1/8” (can be more) below the bottom of the nosecone on the spindle (vac or metal nosecone). You want to make sure the nosecone will not hit the guiderails or anything else while running a job.

If you want to engrave slightly deeper, you can adjust the spindle tension from all the way up (the lightest tension which is what you want for plastic engraving) to about half way down which adds pressure to the spindle but still allows the prox sensor to work.

This pic is the tension adjust for the 810 and 1212 and is all the way up.

This pic is for the tension adjust on 16 and 25 series machines and is half way down.

When it comes to setting up diamond drag jobs, there are step by step instructions in your manuals which should be on your pc/laptop.

Hope this helps, check back later for more tips.